BLOG

Pearl Nano Polishing Compounds

Aug 19, 2021Ceramic Compound and Correction Compound are both used in paint correction to remove scratches, swirls and micro-marring. The difference is how they achieve the end result and how long it takes to do so.

Introduction

Over time, contaminants, like bugs, pollen, and dirt, collect on the surface of your car. Regular washing, no matter how careful you are, causes these microparticles to scratch and dig groves into the clearcoat of your car. Just washing the car will not remove this environmental fallout stuck to the car.

Restoring contaminated, dull, and hazy paint to a clean mirror-like finish requires a high-quality polishing compound to polish down and repair the surface of the clearcoat. Compounds are made with either diminishing or non-diminishing abrasives.

What's the difference between diminishing and non-diminishing?

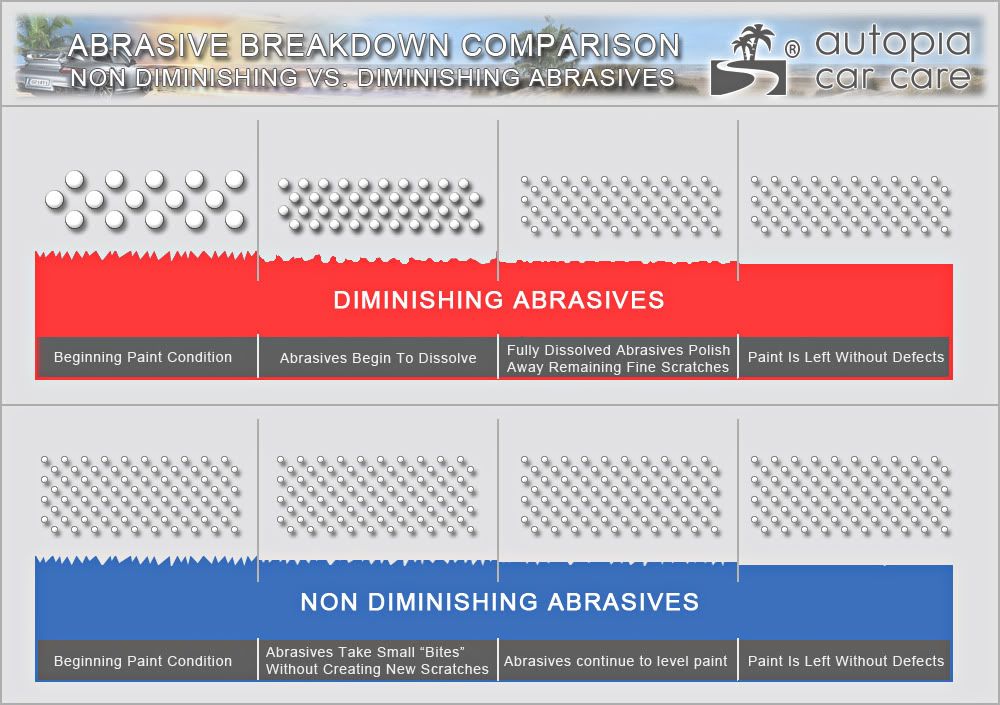

As the title suggests, the difference between diminishing and non-diminishing relates to how the compound’s abrasives breakdown during polishing. These abrasives wear down the surface of the clear coat to create a smooth, scratch-free surface. Compounds suspend these abrasives in oils, solvents and lubricants that help prevent scratching during use, making them safe for all paint systems even fiberglass and gel coats.

A diminishing compound, like Pearl Nano’s all-in-one Correction Compound, has abrasives that break down when exposed to the friction of a polishing pad against the clear coat surface. The “effectiveness” or power to level diminishes over the time spent polishing because the abrasives eventually diminish away. You can use a course pad and then a fine polishing pad, and the same compound to change to results. This compound works very well with either a traditional rotary polisher and the new dual-action polishers.

A non-diminishing compound, like Pearl Nano’s Ceramic Compound, has smaller abrasives that don’t wear down over time — they stay essentially the same size over the course of polishing. The new technology of this product allows for fast, effective polishing on the newer water-borne paint systems. The medium to fine polish results are perfect to create a quick paint enhancement or DIY scratch removal process. It works best with the microfiber cutting and polishing pad on a dual-action polisher. The minimal to no dusting makes cleanup easy.

Below, one of our standout certified installers, Jay from Eco Wash Hawaii further explains the differences between Correction Compound and Ceramic Compound.

Should I use a diminishing or non-diminishing paint correction compound?

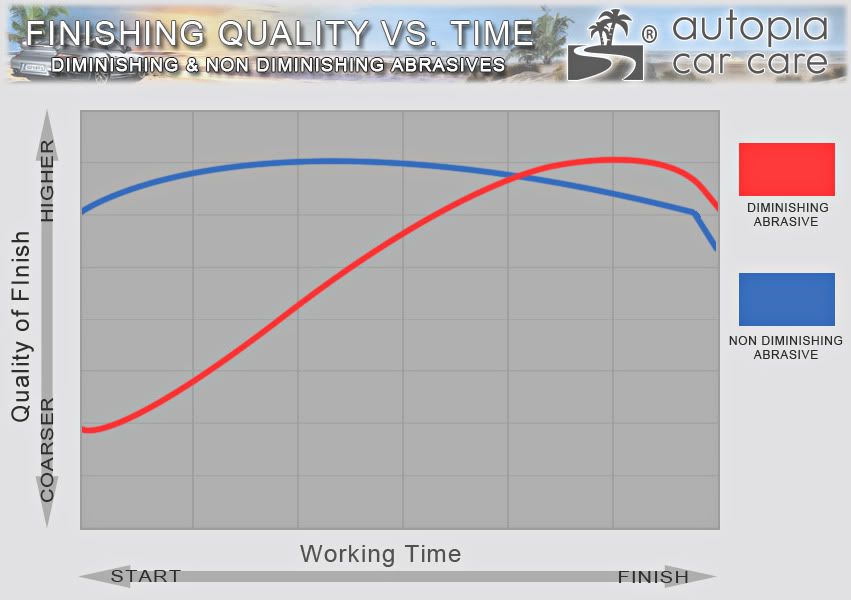

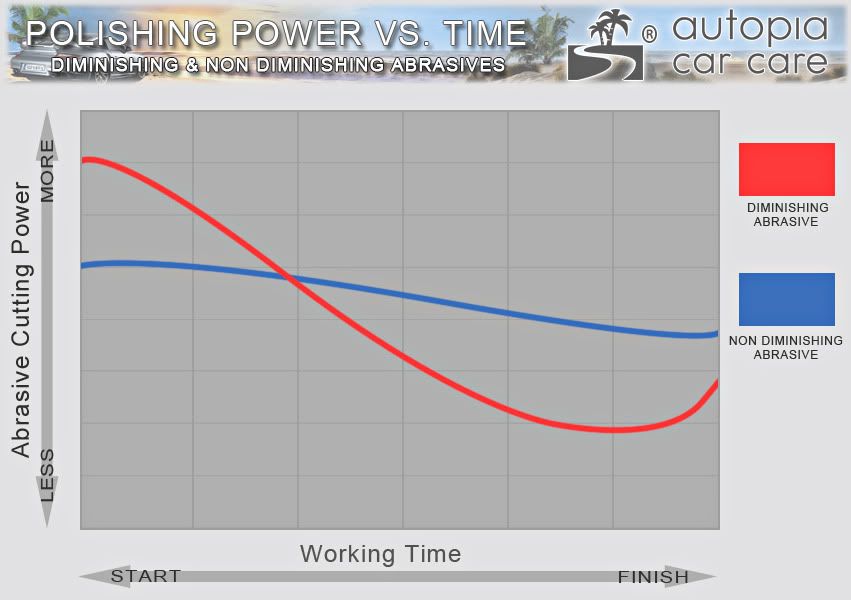

Autopia.com forum user “Todd@RUPES” touched on the differences between diminishing and non-diminishing abrasive polishes; we sourced the graphs below from his great thread.

Diminishing:

- Must fully dissolve the abrasives to achieve the highest quality finish.

- May take multiple applications.

- May take longer to work.

- May not require cascading, or reducing polisher RPM and speed.

Non-Diminishing:

- May require cascading, or reducing the polisher RPM and speed, to finish down nicely.

- Stop as soon as you remove the defects.

Abrasive Breakdown Comparison

Polishing Power V.S. Time

Finishing Quality V.S. Time